| Model | Unit | NSD-80 | NSD-125 | NSD-170 | NSD-210 | NSD-250 | |||

|---|---|---|---|---|---|---|---|---|---|

| Table diameter | mm | ø80 | ø125 | ø170 | ø210 | ø250 | |||

| Center height | mm | 90 | 110 | 135 | 160 | 160 | |||

| Through-hole diameter | mm | 20H7 | 30H7 | 55H7 | 55H7 | 55H7 | |||

| Spindle hole | mm | 20 | 22 | 50 | 40 | 40 | |||

| T-solt width | mm | 12H7 | 12H7 | 12H7 | 12H7 | 12H7 | |||

| Positionning button | mm | 14H7 | 14H7 | 14h7 | 18h7 | 18h7 | |||

| Servo motor modle(Suggest) | FANUC | - | ßis2 | ßis4 | ßis8 | ßis8 | ßis8 | ||

| MITSUBISHI | - | KP73 | HF105 | HF104 | HF104 | HF104 | |||

| Speed reduction ratio | - | 1:40 | 1:48 | 1:75 | 1:75 | 1:75 | |||

| Max.table speed | rpm | 100 | 62.5 | 53.3 | 53.3 | 53.3 | |||

| Min.increment | deg. | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° | |||

| Clamping Torque | Kg-m | 8 | 13 | 31 | 45 | 45 | |||

| Looking Method | pneumatic | kg/cm2 | 6 | 6 | 6 | 6 | 6 | ||

| Allowable work inertia | Kg.cm.sec2 | 1 | 2 | 5.4 | 8.3 | 8.3 | |||

| Allowable cut torque | Kgf-m | 5 | 9 | 20 | 20 | 20 | |||

| Lndexing arccuracy | sec. | 30 | 20 | 20 | 20 | 20 | |||

| Repeatability | sec. | 4 | 4 | 4 | 4 | 4 | |||

| Max.load | Vertical | kg | 25 | 50 | 80 | 80 | 80 | ||

| Horizontal | kg | 50 | 80 | 160 | 160 | 160 | |||

| Tailstok applied | kg | 50 | 80 | 160 | 160 | 200 | |||

| Weight(motor excluded) | kg | 25 | 35 | 50 | 60 | 65 | |||

| Model | Unit | NSD-255 | NSD-255H | NSD-320 | NSD-400 | NSD-500 | NSD-630 | NSD-800 | |

| Table diameter | mm | ø255 | ø255 | ø320 | ø400 | ø500 | ø630 | ø800 | |

| Center height | mm | 160 | 190 | 210 | 255 | 310 | 400 | 500 | |

| Through-hole diameter | mm | 80H7 | 80H7 | 110H7 | 150H7 | 250H7 | 300H7 | 350H7 | |

| Spindle hole | mm | 80 | 80 | 110 | 115 | 220 | 280 | 350 | |

| T-solt width | mm | 12H7 | 12H7 | 14H7 | 14H7 | 18H7 | 18H7 | 18H7 | |

| Positionning button | mm | 18h7 | 18h7 | 18h7 | 18h7 | 18h7 | 22h7 | 22h7 | |

| Servo motor modle(Suggest) | FANUC | - | ßis8 | ßis8 | ßis22 | ßis22 | ßis22 | ßis30 | ßis40 |

| MITSUBISHI | - | HF154 | HF154 | HF204 | HF204 | HF204 | HF453 | HF453 | |

| Speed reduction ratio | - | 1:120 | 1:120 | 1:120 | 1:120 | 1:180 | 1:240 | 1:360 | |

| Max.table speed | rpm | 33.3 | 33.3 | 33.3 | 33.3 | 22.2 | 16.6 | 11.1 | |

| Min.increment | deg. | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° | |

| Clamping Torque | Kg-m | 70 | 70 | 115 | 200 | 370 | 800 | 950 | |

| Looking Method | hydraulic | kg/cm2 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Allowable work inertia | Kg.cm.sec2 | 20.3 | 20.3 | 44.8 | 100 | 200 | 396.6 | 1200 | |

| Allowable cut torque | Kgf-m | 55 | 55 | 80 | 170 | 270 | 800 | 950 | |

| Lndexing arccuracy | sec. | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

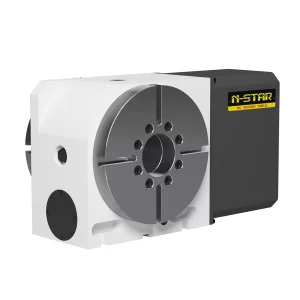

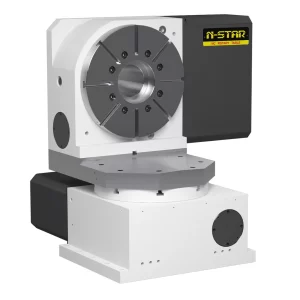

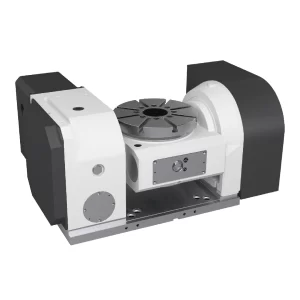

Rotary Indexing Tables

Rotary Indexing Tables

Product features

-

Rang from 3 inch to 32 inch in diameter

-

Diameter from 80mm to 800mm

-

Mounted by Vertical or Horizontal

-

Penduem or Hydraulic options

-

Various workholding or cnctooling options

Optional Accessories

-

Tailtock (manual/pneumatic/hydrulic thimble tailtock)

-

servo motor and amplifer for any systems(Fanuc,Mitsubishi,Siemens,etc.)

-

Matching cambles or wires

-

chucks (Manual/Hydraulic chucks, three-jaw or four-jaw options )